深圳市鼎泰佳创科技有限公司

产品名称:自动测试老化生产线

Product name: Automatic burn-in testing production manufacturing line

产品型号:DTJC-ATL50

Product Model: DTJC-ATL50

产品应用范围:各类型适配器/电源产品自动测试及老化.

Product application field: Different power adapter/power source automatic testing and burn-in

产品功能特点:1.老化与测试治具共用,并且可试用于多种产品,换线只需调出已存储相关程序即可,自动化程度高,整个生产过程最多需要2人.

Product features: 1. Jig for both testing and burn-in purpose, it can be used for different product, by simply load the program to change the production line, it only need two operators to operate the whole production line.

2.具备自动初测、自动老化、自动高压测试、自动ATE测试、良品/不良品自动分类取出,节省劳动力提高生产效率.

2. Automatic pre-testing, automatic burn-in, automatic high voltage testing, automatic ATE testing, automatic Pass/Fail sorting, labor saving and high production efficiency.

3.老化测试过程实时监测、测试结果自动实时追踪,具有异常报警停机功能,相关数据报表可上传及下载 .

3.Burn-in processing real-time monitoring, testing data real-time tracking and uploading/downloading, alarm for abnormal operation.

4.内部温度智能循环控制系统,实时监控,精准控制.

4.Internal intelligent temperature control system for real-time temperature monitoring and controlling.

5.使用节能老化负载,回收效率达80%以上,同时节省老化测试用电,减少负载散热用电,降低设备主电配置用电.

5. Energy-saving electronic loads can recycle power up to 80%, saving the power and reduce the heat, low down the power line load.

6.采用倍速链流水线式输送作业,机械手搬运夹取,PLC+HMI+PC控制,智能可靠,操作简单,维护方便.

6. Chain assembly line, manipulator picking and moving, PLC+HMI+PC combination control provides intelligent ,reliable, easy operation, easy maintenance.

7.老化测试接口采用专用连接器,老化测试稳定可靠,便于后期维护更换,节约成本。

7.Customize Burn-in testing connectors provide reliable burn-in and testing, easy maintenance, saving cost.

8.整机采用模块化加人机工程学设计,结构简单,稳定可靠,可根据客户要求进行定制化配置.

8. Modulation and ergonomics design provide compact structure, stable and reliable, machine can be customized according to customer requirements.

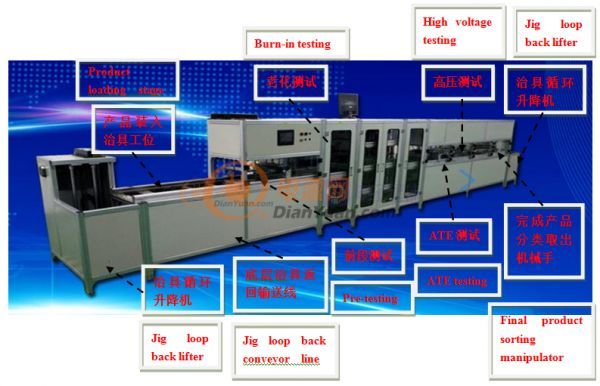

工作流程说明:空治具进入产品装入工位→人工装入产品→前段测试→老化测试→ATE测试→高压测试→良品/不良品取出分类放置→空治具进入尾端升降机→底层空治具返回输送线→前端升降机→产品装入治具工位

Description of work flow: Empty jig move into product loading stage → operator load product → pre-testing → burn-in testing → ATE testing → High voltage testing → OK/NG product sorting → empty jig flow into back end lifter → jig enter loop back conveyor line → jig flow into front end lifter → Product loading stage