admin,plaz allowed me to make another thread about my EPS system! Anyone who wanna make such EPS sys, I could be very happy to offer help!

further more, If you think my EPS inverter sys is steadiness & reliability via our technic discussion we could make further cooperation to develope this market field and our technology!

我的EPS性能指标!

全部回复(25)

正序查看

倒序查看

现在还没有回复呢,说说你的想法

These days I'm crazy busy,I was in many troubles during the last past 2 months, and now It's seems that my nightmare is coming to the end, becouse I've finished the 0.5KW~3KW EPS series models and all destroyer test numbers shows the sys works well.

Some part test result as follow,

Machine model: BD-S3KW(EPS-3KW)

Temp:23℃

Humi:80%

-------------------------------------------------

1,inverter status empty loade test

battery voltage:54V

output voltage:220V

frequency:50HZ

battery current:0.67A

noise:<40dB

------------------------------------------

2 inverter status full loade test

loade:600W(resistance)+1.7kw(fluorescence lights,Λ=0.6)+1.5kw(air compressor)

soft start: OK

full loade concuss test:OK

efficiency:98%

sine wave distortion: bad distortion of course can work

------------------------------------

3 charge test

totale time<20h ,When the battery charged to 95%

Some part test result as follow,

Machine model: BD-S3KW(EPS-3KW)

Temp:23℃

Humi:80%

-------------------------------------------------

1,inverter status empty loade test

battery voltage:54V

output voltage:220V

frequency:50HZ

battery current:0.67A

noise:<40dB

------------------------------------------

2 inverter status full loade test

loade:600W(resistance)+1.7kw(fluorescence lights,Λ=0.6)+1.5kw(air compressor)

soft start: OK

full loade concuss test:OK

efficiency:98%

sine wave distortion: bad distortion of course can work

------------------------------------

3 charge test

totale time<20h ,When the battery charged to 95%

0

回复

提示

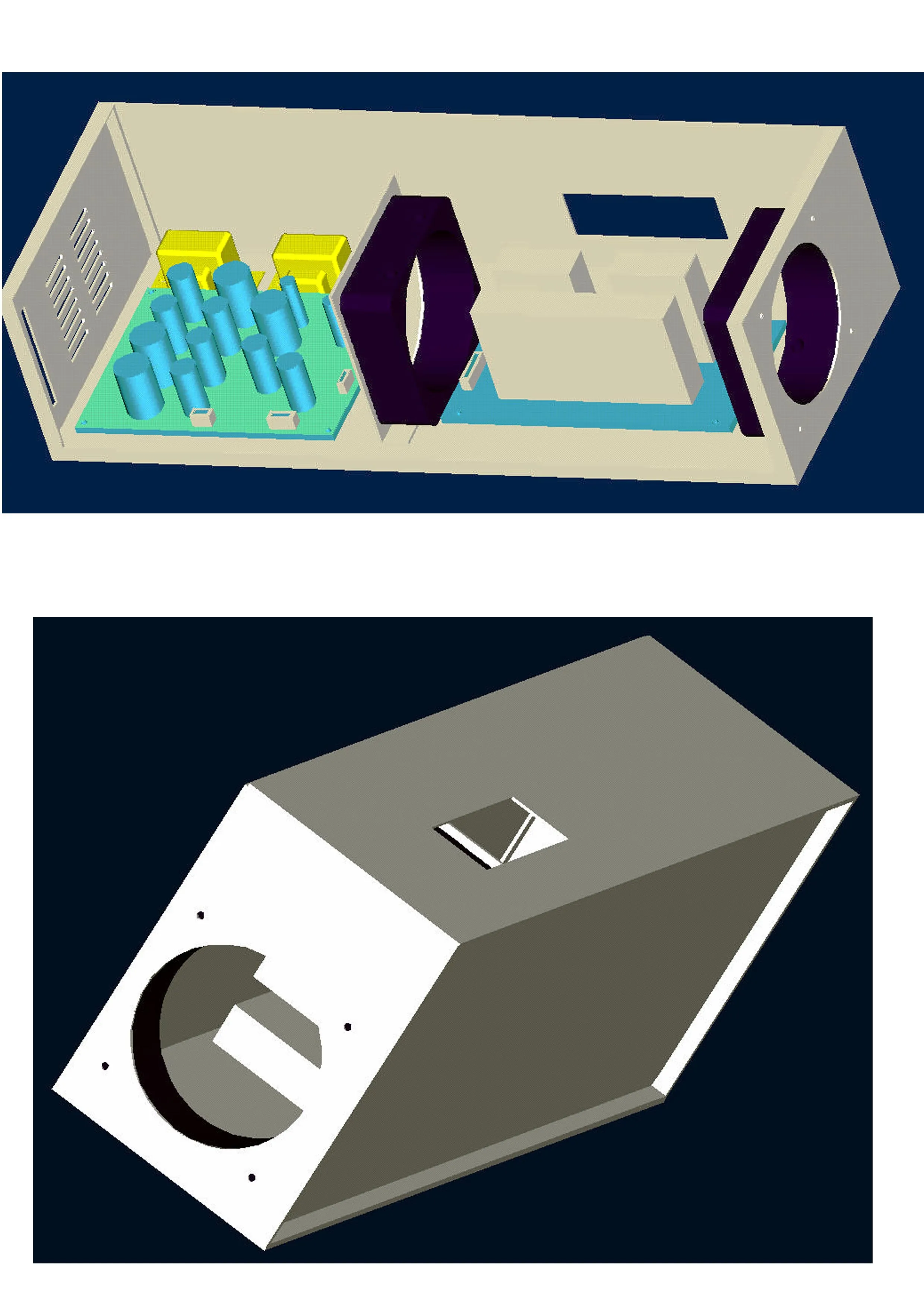

Inner structure design in 3D which make us easy to control the details!!!!

500) {this.resized=true; this.width=500; this.alt='这是一张缩略图,点击可放大。\n按住CTRL,滚动鼠标滚轮可自由缩放';this.style.cursor='hand'}" onclick="if(!this.resized) {return true;} else {window.open('http://u.dianyuan.com/bbs/u/40/1145861373.jpg');}" onmousewheel="return imgzoom(this);">

500) {this.resized=true; this.width=500; this.alt='这是一张缩略图,点击可放大。\n按住CTRL,滚动鼠标滚轮可自由缩放';this.style.cursor='hand'}" onclick="if(!this.resized) {return true;} else {window.open('http://u.dianyuan.com/bbs/u/40/1145861373.jpg');}" onmousewheel="return imgzoom(this);">

500) {this.resized=true; this.width=500; this.alt='这是一张缩略图,点击可放大。\n按住CTRL,滚动鼠标滚轮可自由缩放';this.style.cursor='hand'}" onclick="if(!this.resized) {return true;} else {window.open('http://u.dianyuan.com/bbs/u/40/1145861373.jpg');}" onmousewheel="return imgzoom(this);">

500) {this.resized=true; this.width=500; this.alt='这是一张缩略图,点击可放大。\n按住CTRL,滚动鼠标滚轮可自由缩放';this.style.cursor='hand'}" onclick="if(!this.resized) {return true;} else {window.open('http://u.dianyuan.com/bbs/u/40/1145861373.jpg');}" onmousewheel="return imgzoom(this);"> 0

回复

提示

@zack

Innerstructuredesignin3Dwhichmakeuseasytocontrolthedetails!!!![图片]500){this.resized=true;this.width=500;this.alt='这是一张缩略图,点击可放大。\n按住CTRL,滚动鼠标滚轮可自由缩放';this.style.cursor='hand'}"onclick="if(!this.resized){returntrue;}else{window.open('http://u.dianyuan.com/bbs/u/40/1145861373.jpg');}"onmousewheel="returnimgzoom(this);">

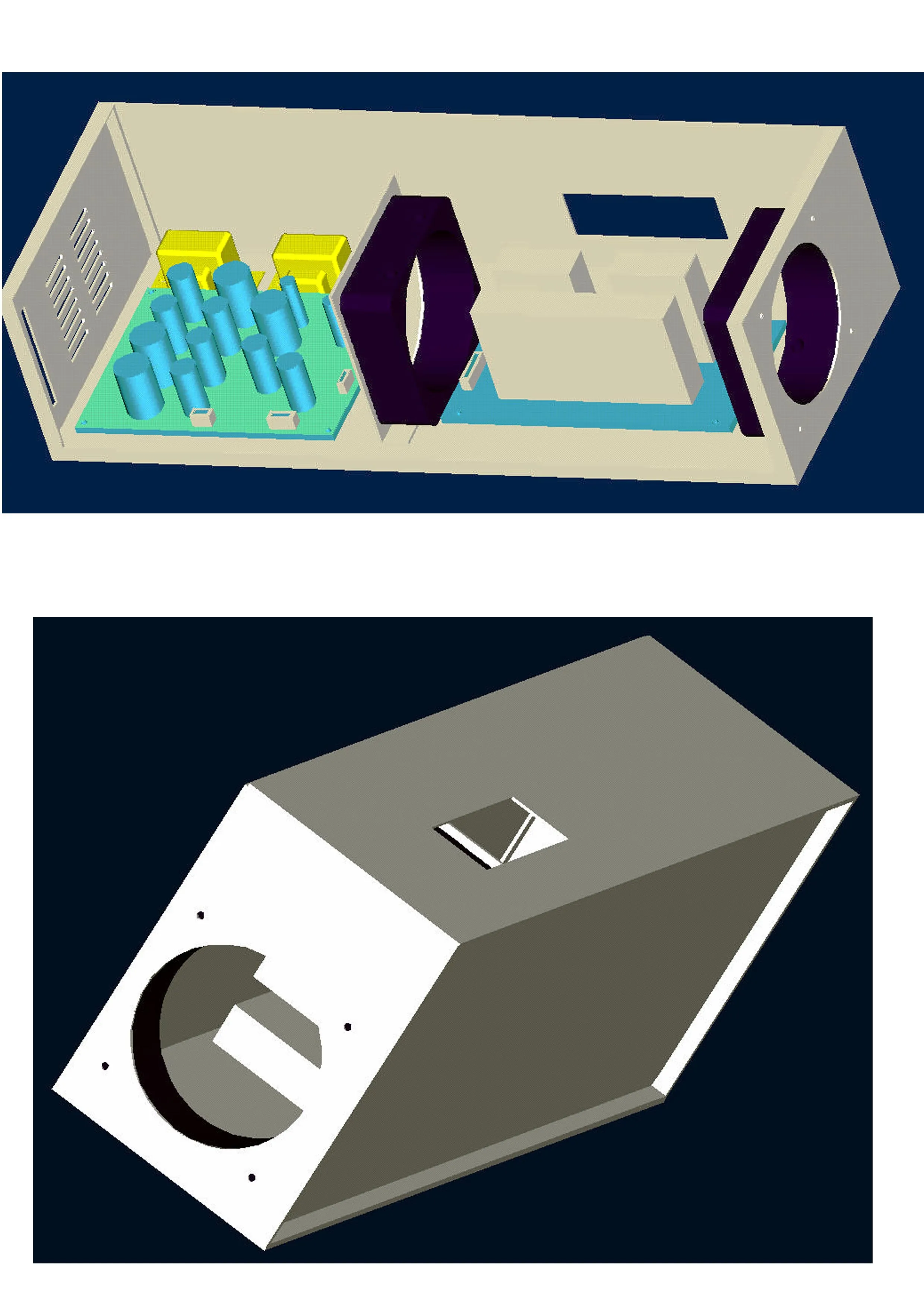

Main inverter sys module struture! And We own the patent right,which make the after service very convenience and easy!!

500) {this.resized=true; this.width=500; this.alt='这是一张缩略图,点击可放大。\n按住CTRL,滚动鼠标滚轮可自由缩放';this.style.cursor='hand'}" onclick="if(!this.resized) {return true;} else {window.open('http://u.dianyuan.com/bbs/u/40/1145862459.jpg');}" onmousewheel="return imgzoom(this);">

500) {this.resized=true; this.width=500; this.alt='这是一张缩略图,点击可放大。\n按住CTRL,滚动鼠标滚轮可自由缩放';this.style.cursor='hand'}" onclick="if(!this.resized) {return true;} else {window.open('http://u.dianyuan.com/bbs/u/40/1145862459.jpg');}" onmousewheel="return imgzoom(this);">

500) {this.resized=true; this.width=500; this.alt='这是一张缩略图,点击可放大。\n按住CTRL,滚动鼠标滚轮可自由缩放';this.style.cursor='hand'}" onclick="if(!this.resized) {return true;} else {window.open('http://u.dianyuan.com/bbs/u/40/1145862459.jpg');}" onmousewheel="return imgzoom(this);">

500) {this.resized=true; this.width=500; this.alt='这是一张缩略图,点击可放大。\n按住CTRL,滚动鼠标滚轮可自由缩放';this.style.cursor='hand'}" onclick="if(!this.resized) {return true;} else {window.open('http://u.dianyuan.com/bbs/u/40/1145862459.jpg');}" onmousewheel="return imgzoom(this);"> 0

回复

提示

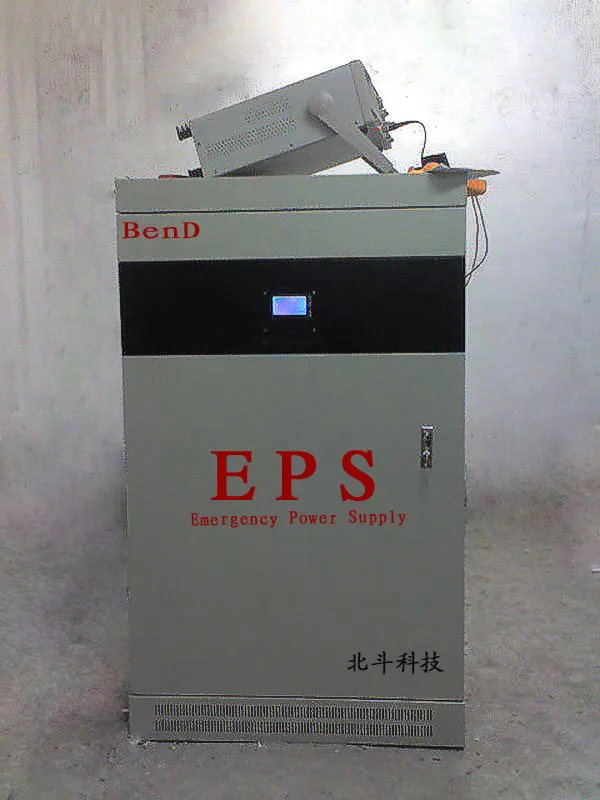

the finished product appearance!

500) {this.resized=true; this.width=500; this.alt='这是一张缩略图,点击可放大。\n按住CTRL,滚动鼠标滚轮可自由缩放';this.style.cursor='hand'}" onclick="if(!this.resized) {return true;} else {window.open('http://u.dianyuan.com/bbs/u/40/1145862646.jpg');}" onmousewheel="return imgzoom(this);">

500) {this.resized=true; this.width=500; this.alt='这是一张缩略图,点击可放大。\n按住CTRL,滚动鼠标滚轮可自由缩放';this.style.cursor='hand'}" onclick="if(!this.resized) {return true;} else {window.open('http://u.dianyuan.com/bbs/u/40/1145862646.jpg');}" onmousewheel="return imgzoom(this);">

500) {this.resized=true; this.width=500; this.alt='这是一张缩略图,点击可放大。\n按住CTRL,滚动鼠标滚轮可自由缩放';this.style.cursor='hand'}" onclick="if(!this.resized) {return true;} else {window.open('http://u.dianyuan.com/bbs/u/40/1145862646.jpg');}" onmousewheel="return imgzoom(this);">

500) {this.resized=true; this.width=500; this.alt='这是一张缩略图,点击可放大。\n按住CTRL,滚动鼠标滚轮可自由缩放';this.style.cursor='hand'}" onclick="if(!this.resized) {return true;} else {window.open('http://u.dianyuan.com/bbs/u/40/1145862646.jpg');}" onmousewheel="return imgzoom(this);"> 0

回复

提示

@zack

thefinishedproductappearance![图片]500){this.resized=true;this.width=500;this.alt='这是一张缩略图,点击可放大。\n按住CTRL,滚动鼠标滚轮可自由缩放';this.style.cursor='hand'}"onclick="if(!this.resized){returntrue;}else{window.open('http://u.dianyuan.com/bbs/u/40/1145862646.jpg');}"onmousewheel="returnimgzoom(this);">

**此帖已被管理员删除**

0

回复

提示

@zack

都有.目前是按照载波16KHZ频率设计.xzszrs兄,假如我把SPWM载频提高到100KHZ可以大幅度降低变压器体积.你说呢?

我说嘛,变压器输入的是两种信号成分:工频和载频,输出的是工频,也就是说传递的功率信号是工频,所以它必需按照工频变压器的标准设计,另一方面,它又要考滤载频的输入损耗,包扩铜损和铁损,这里忽略铜损,主要考滤铁损,铁损随载频的升高并不是线性减小的,在5K以下下降曲线较陡,5K-20K下降缓慢,20K以上还会从某个点缓慢增加.所以说提高载频很难大幅度减小工频变压器的体积.提高载频到一定成度就只能白白地增加开关损耗了.SPWM工频变压器是工频变压器,但又比工频变压器要求高,要减小体积除了要合理选择载频外,更要选择高导磁率高饱和点的铁芯,

要大幅度减小EPS整机的体积只有做高频机,彻底地革除工频主变!

要大幅度减小EPS整机的体积只有做高频机,彻底地革除工频主变!

0

回复

提示

@xzszrs

我说嘛,变压器输入的是两种信号成分:工频和载频,输出的是工频,也就是说传递的功率信号是工频,所以它必需按照工频变压器的标准设计,另一方面,它又要考滤载频的输入损耗,包扩铜损和铁损,这里忽略铜损,主要考滤铁损,铁损随载频的升高并不是线性减小的,在5K以下下降曲线较陡,5K-20K下降缓慢,20K以上还会从某个点缓慢增加.所以说提高载频很难大幅度减小工频变压器的体积.提高载频到一定成度就只能白白地增加开关损耗了.SPWM工频变压器是工频变压器,但又比工频变压器要求高,要减小体积除了要合理选择载频外,更要选择高导磁率高饱和点的铁芯, 要大幅度减小EPS整机的体积只有做高频机,彻底地革除工频主变!

我指的变压器设计是采用铁氧体磁心的EE-70的高频变压器.

假如任然按照工频设计显然会硅刚片饱和,损耗增加,温度直线上升!

必须按照200KHZ的频率设计高频变压器.

结果主要考虑是否会带载性能下降.

假如结果只能带一些容阻性负载,那也没多大意义.

假如任然按照工频设计显然会硅刚片饱和,损耗增加,温度直线上升!

必须按照200KHZ的频率设计高频变压器.

结果主要考虑是否会带载性能下降.

假如结果只能带一些容阻性负载,那也没多大意义.

0

回复

提示

500) {this.resized=true; this.width=500; this.alt='这是一张缩略图,点击可放大。\n按住CTRL,滚动鼠标滚轮可自由缩放';this.style.cursor='hand'}" onclick="if(!this.resized) {return true;} else {window.open('http://u.dianyuan.com/bbs/u/40/1145854716.jpg');}" onmousewheel="return imgzoom(this);">

500) {this.resized=true; this.width=500; this.alt='这是一张缩略图,点击可放大。\n按住CTRL,滚动鼠标滚轮可自由缩放';this.style.cursor='hand'}" onclick="if(!this.resized) {return true;} else {window.open('http://u.dianyuan.com/bbs/u/40/1145854716.jpg');}" onmousewheel="return imgzoom(this);">